Dab tsi yog dej soluble fertilizer?

Dej-soluble fertilizer yog ib hom kev ua chiv sai, muaj cov dej zoo solubility, nws tuaj yeem yaj hauv dej tsis muaj residue, thiab nws tuaj yeem nqus tau thiab siv ncaj qha los ntawm cov hauv paus system thiab nplooj ntawm cov nroj tsuag.Qhov nqus thiab siv tus nqi tuaj yeem ncav cuag 95%.Yog li ntawd, nws muaj peev xwm ua tau raws li cov kev xav tau ntawm kev noj haus ntawm cov qoob loo uas muaj txiaj ntsig zoo nyob rau theem kev loj hlob sai.

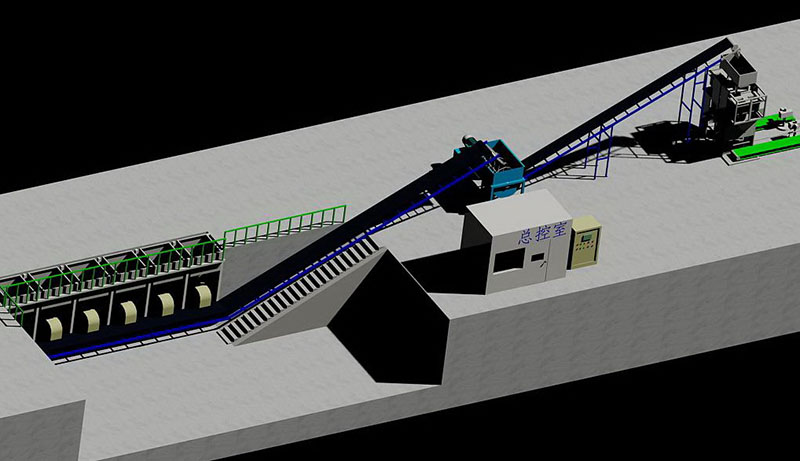

Kev taw qhia luv luv ntawm cov dej soluble fertilizer ntau lawm kab.

Taw qhiaof Dej-soluble fertilizer ntau lawm kab

Dej-soluble fertilizer ntau lawm kab yog cov khoom siv chiv tshiab.Qhov no suav nrog kev pub khoom noj, batching, sib tov thiab ntim khoom.Sib tov 1 ~ 5 cov ntaub ntawv raw raws li cov qauv chiv, thiab tom qab ntawd cov ntaub ntawv raug ntsuas, ntim thiab ntim.

Peb Cov Khoom Siv Hluav Taws Xob Static batching dej-soluble fertilizer ntau lawm kab tuaj yeem tsim ib lub hnab ntawm 10-25kg dej-soluble fertilizer khoom, siv cov kev tswj hwm thoob ntiaj teb siab tshaj plaws, sab hauv lossis sab nraud high-precision sensors, nws muaj cov qauv compact, meej batching, txawm sib tov , raug ntim.Feem ntau haum rau loj zus tau tej cov dej soluble fertilizer manufacturers.

(1) Cov cuab yeej tswj kev tshaj lij

Cov khoom noj tshwj xeeb, zoo li qub batching nplai, sib sib zog nqus sib xyaw, tshwj xeeb ntim tshuab rau sau cov dej soluble chiv, kev tshaj lij conveyor, tsis siv neeg tshuab xaws.

(2) Cov txheej txheem ntau lawm

Khoom noj khoom haus-khoom siv crusher-Linear tshuaj ntsuam tshuab - thoob of elevator - khoom distributor - kauv conveyor - Khoos phib tawj static batching - sib tov tshuab - ntau ntim tshuab

(3) Khoom Parameter:

1. Ntau lawm muaj peev xwm: 5 tons;

2. Cov khoom xyaw: 5 hom;

3. Batching instrument: 1 teeb;

4. Batching peev: 5 tons ntawm dej-soluble chiv ib teev;

5. Batching daim ntawv: static batching;

6. Cov khoom xyaw precision: ± 0.2%;

7. Sib tov daim ntawv: quab yuam tov khoom;

8. Kev sib xyaw muaj peev xwm: 5 tons sib xyaw ua ke ib teev;

9. Daim ntawv thauj khoom: siv los yog thoob of elevator;

10. Ntim ntau: 10-25 kg;

11. Ntim muaj peev xwm: 5 tons ib teev;

12. Ntim qhov tseeb: ± 0.2%;

13. Ib puag ncig adaptation: -10 ℃ ~ + 50 ℃;

Taw qhia ntawm cov cuab yeej tseem ceeb ntawm cov dej-soluble fertilizer ntau lawm kab

Cia rau hauv: Cia cov khoom tuaj rau kev ua

Lub hauv paus yog muab tso rau saum lub tshuab ntim khoom thiab txuas ncaj qha nrog lub flange ntawm lub tshuab ntim khoom.Lub valve yog teem rau hauv qab ntawm qhov chaw cia khoom rau kev saib xyuas lossis kaw lub sijhawm ntawm cov khoom noj;Lub phab ntsa ntawm lub thawv cia yog nruab nrog sab sauv thiab qis nres spinning qib keyboards rau kev saib xyuas cov khoom siv.Thaum cov khoom nkag tau dhau los ntawm qhov chaw nres tsheb sab sauv tig, lub tshuab nqus tsev noj mov yog tswj kom tsis txhob pub mis.Thaum nws tsawg dua qhov qis dua qhov hloov pauv hloov pauv, lub tshuab ntim khoom yuav tsum tsis txhob ua haujlwm thiab lub xeev lub teeb yuav flash.

Qhov hnyav scale feeding system

Qhov no series ntawm hluav taws xob scale pub system, adopts zaus hloov dua siab tshiab tswj, muaj loj, me me thiab instantaneous nres noj hom, loj pub noj tswj ntim ceev, me me tswj kev ntim khoom raug.Nyob rau hauv cov ntaub ntawv ntawm 25kg ntim, 5% pub me me yog saws thaum pub mis loj mus txog 95%.Yog li ntawd, txoj kev pub mis no tuaj yeem tsis tsuas yog lav lub ntim ceev tab sis kuj lav lub ntim precision.

Kev ntsuas qhov system

Cov txheej txheem pub mis yog pub ncaj qha rau hauv lub hnab ntim khoom los ntawm lub thawv cia.Nws yog zoo tsim, nrog me me poob sib txawv thiab zoo sealing.Lub cev lub cev raug tshem tawm thiab kho ntawm lub sensor (sensor kev ua haujlwm: tso zis rhiab heev: 2MV / V qhov tseeb theem: 0.02 repeatability: 0.02%; Kub them nyiaj ntau: -10 ~ 60 ℃; Kev ua haujlwm kub ntau -20 ~ + 65 ℃; Tso cai overload : 150%), kom nws tsis muaj kev sib cuag nrog sab nraud kom ua tiav qhov tseeb dua.

Clamping hnab khoom

Txais cov khoom siv los tiv thaiv plam thiab hnav-tiv taus, nws tuaj yeem hloov kho qhov dav ntawm qhov ntim raws li lub hnab ntawm cov khoom sib txawv, thiab lub qhov rooj tawm yuav qhib tau tom qab lub hnab ntim tom ntej, thiab kev pub mis yuav pib dua;Nws txais yuav lub hnab kaw clamping qauv thiab tsav los ntawm lub tog raj kheej, nws yooj yim rau kev khiav lag luam thiab yooj yim rau kev txij nkawm.

Conveyor

Adjustable qhov siab, adjustable ceev, tuaj yeem tig los yog thim rov qab, ob sab ntawm txoj siv nrog cov phaj tiv thaiv, tuaj yeem ua rau lub hnab tsis sib txawv thiab tawg;Tus qauv ntev yog 3m, thiab cov hnab ntim tau raug thauj mus rau lub tshuab xaws rau xaws.

Tshuab xaws

Nrog tsis siv neeg xaws muaj nuj nqi.

Max ceev: 1400 RPM;

Qhov siab tshaj plaws xaws thickness: 8mm,

Stitch hloov ntau yam: 6.5 ~ 11mm;

Sewing xov stitch hom: ob txoj xov saw;

Sewing specifications: 21s / 5;20/3 Polyester kab;

Lifting qhov siab ntawm presser ko taw: 11-16mm;

Tshuab koob qauv: 80800 × 250 #;

Lub Zog: 370 W;

Vim tias lub hnab ntim qhov siab yog qhov tsis paub meej, lub hau ntswj nqa lub tshuab tau teeb tsa rau hauv kem, kom nws tuaj yeem siv rau lub hnab ntawm qhov siab sib txawv;Sab hauv yog muab nrog lub rooj zaum coil rau tso lub coil;

Tswj qhov system

Txais yuav batching instrument tswj system, lub kaw lus muaj kev ruaj ntseg thiab zoo corrosion kuj (sealing);Tsis siv neeg poob kho muaj nuj nqi;Tsis siv neeg xoom taug qab muaj nuj nqi;Ntsuas thiab tsis siv neeg lub tswb muaj nuj nqi;Nws tuaj yeem ua haujlwm manually lossis txiav.Ob hom tuaj yeem hloov tau txhua lub sijhawm.

Kev ua haujlwm:

Qhib lub hwj chim hloov thiab xyuas seb lub hwj chim taw qhia puas qhib.Yog tias tsis yog, xyuas seb lub hwj chim txuas puas zoo.

Txawm hais tias txhua qhov chaw ua haujlwm ib txwm nyob hauv lub xeev phau ntawv;

Teem cov qauv (cov qauv tuaj yeem ua raws li phau ntawv ua haujlwm).

Qhib tsis siv neeg.

Ib tug neeg yuav muab lub hnab tso rau hauv qhov qhib qhov chaw tsis siv neeg, thiab lub hnab yuav pib sau cia.Tom qab lub filling, lub hnab yuav so kom txaus.

Lub hnab poob yuav raug thauj mus rau lub tshuab xaws rau xaws los ntawm lub conveyor.

Tag nrho cov txheej txheem ntim khoom tiav.

Qhov zoo ntawm cov dej-soluble fertilizer ntau lawm kab:

1. Cov txheej txheem batching txais cov txheej txheem zoo li qub batching tswj cov khoom tseem ceeb;

2. Vim yog qhov tsis zoo ntawm cov dej-soluble fertilizer raw cov ntaub ntawv, ib qho kev pub mis tshwj xeeb yog saws los xyuas kom meej cov txheej txheem pub mis zoo ntawm cov khoom siv raw yam tsis muaj kev thaiv.

3. Static batching txoj kev yog saws nyob rau hauv batching scale kom paub meej batching thiab cov batching tus nqi yog siv nyob rau hauv 8 tons ib teev twg;

4, Siv lub thoob of elevator rau kev pub mis (qhov zoo: kev tiv thaiv corrosion, lub neej ntev, zoo sealing nyhuv, tsis ua hauj lwm tus nqi; me me pem teb chaw; Tsim raws li cov neeg siv khoom qhov chaw thiab cov kev xav tau);

5. Lub ntim ntsuas ntsuas ntsuas tau raug rau 0.2%.

6. Vim yog corrosivity ntawm cov dej soluble chiv, qhov chaw sib cuag ntawm cov kab ntau lawm no yog ua los ntawm lub teb chaws tus qauv stainless hlau nrog tuab, muaj zog thiab ruaj daim hlau.

Tej teeb meem ntawm dej soluble chiv thiab kev tiv thaiv kev ntsuas

Moisturizing thiab agglomerating

Qhov tshwm sim ntawm kev nqus dej noo thiab agglomerating tshwm sim tom qab cov khoom tiav tau khaws cia rau lub sijhawm.

Yog vim li cas: nws muaj feem xyuam rau hygroscopicity ntawm raw cov ntaub ntawv, cov ntsiab lus dej ntawm cov ntaub ntawv, txheeb ze humidity ntawm ntau lawm ib puag ncig, thiab dej nqus cov ntaub ntawv ntim.

Kev daws: Ua tib zoo khaws cov ntaub ntawv raw, tshawb xyuas cov ntaub ntawv tshiab raws sijhawm, tuaj yeem siv hydrated magnesium sulfate agglomerating tus neeg sawv cev.

2. Ntim flatulence

Tom qab cov khoom muab tso rau ib lub sij hawm nyob rau hauv lub caij ntuj sov, roj yog generated nyob rau hauv lub ntim ntim, ua rau lub ntim rau bulge los yog tawg.

Yog vim li cas: Nws feem ntau yog vim cov khoom muaj urea, thiab cov pa roj carbon dioxide feem ntau yog carbon dioxide.

Kev daws: siv cov khoom ntim aerated, xyuam xim rau qhov ntsuas kub ntawm cov khoom tiav.

3. Corrosion ntawm cov khoom ntim

Yog vim li cas: Qee cov qauv yuav corrode cov khoom ntim.

Kev daws: Ua tib zoo xaiv cov khoom ntim, xaiv cov khoom ntim yuav tsum xav txog cov khoom siv raw thiab cov qauv.

Post lub sij hawm: Sep-27-2020