Cov kab ntau lawm txhua xyoo ntawm 30,000 tons ntawm cov organic chiv yog hloov txhua yam ntawm cov organic pov tseg rau hauv cov organic chiv los ntawm cov txheej txheem sib txawv.Bioorganic fertilizer factories tuaj yeem tsis tsuas yog tig qaib quav thiab pov tseg rau hauv cov khoom muaj nqis, tsim cov txiaj ntsig kev lag luam, tab sis kuj txo cov pa phem ib puag ncig thiab tsim cov txiaj ntsig ib puag ncig.Cov duab ntawm cov khoom tuaj yeem yog cylindrical lossis spherical, uas yooj yim rau kev thauj thiab siv.Cov cuab yeej tuaj yeem xaiv tau raws li koj qhov xav tau tiag tiag.

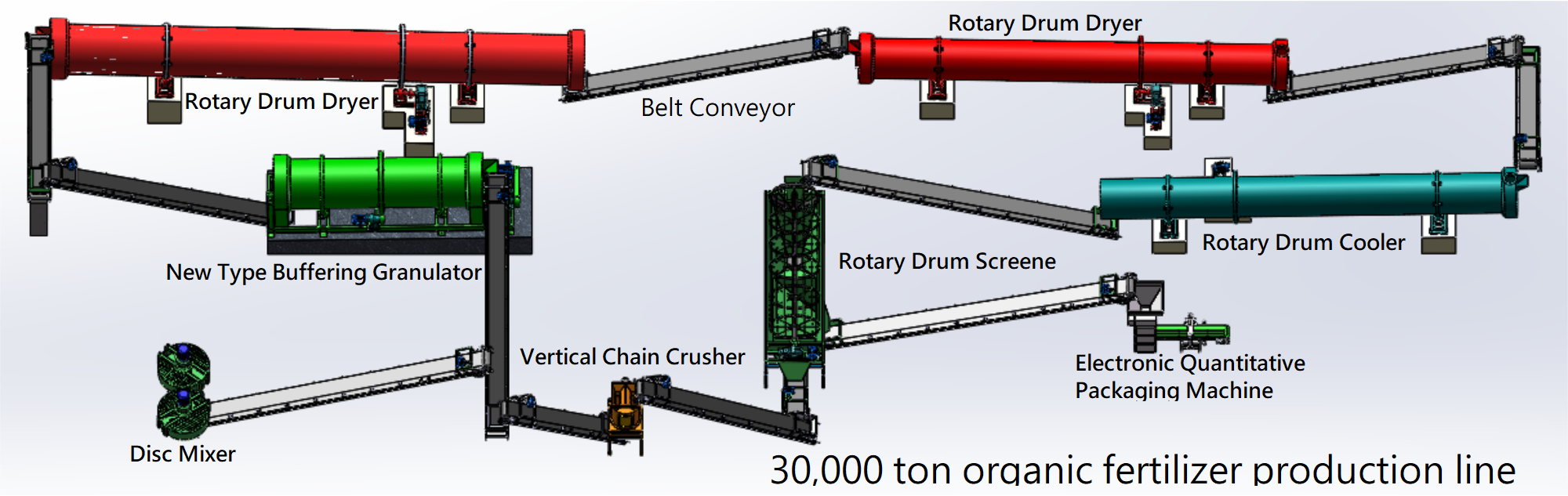

Peb muab cov txheej txheem tsim thiab tsim cov kab tshiab tsis muaj granulation ntau lawm rau cov organic chiv.Cov cuab yeej siv ntau lawm suav nrog lub hopper thiab feeder, lub tshuab tshiab tsis muaj granulation, lub tshuab ziab khaub ncaws, lub tshuab rau cov menyuam, lub thoob hoist, siv conveyor, lub tshuab ntim khoom thiab lwm yam khoom siv.

Organic chiv tuaj yeem ua los ntawm methane residue, kev ua liaj ua teb pov tseg, tsiaj txhu thiab nqaij qaib quav thiab cov khib nyiab hauv nroog.Cov pov tseg cov organic no yuav tsum tau ua tiav ua ntej lawv hloov mus rau hauv kev lag luam organic chiv ntawm cov nqi lag luam muag.Kev nqis peev hauv kev hloov pov tseg rau hauv kev nplua nuj yog qhov tsim nyog tiag tiag.

Organic fertilizer raw cov ntaub ntawv yog nplua nuj nyob rau hauv cov kev pab cuam, uas feem ntau yog muab faib ua pawg hauv qab no.Cov khoom sib txawv tuaj yeem ua ke nrog cov khoom siv sib txawv:

1. Tsiaj tso zis: xws li qaib, npua, duck, nyuj, yaj, nees, luav, thiab lwm yam., tsiaj txhu, xws li ntses, pob txha noj, plaub, plaub, pluab, silkworm manure, biogas pas dej ua ke, thiab lwm yam.

2. Agricultural pov tseg: qoob loo straw, rattan, soybean pluas noj, rapeseed pluas noj, cottonseed pluas noj, silk melon pluas, poov xab hmoov, nceb residue, thiab lwm yam.

3. Muaj pov tseg: cawv slurry, vinegar residue, cassava residue, lim av nkos, tshuaj residue, furfural slag, thiab lwm yam.

4. Municipal sludge: dej av nkos, sludge, ditch av nkos, hiav txwv av, pas dej av, humic acid, turf, lignite, sludge, ya tshauv, thiab lwm yam.

5. Cov khib nyiab hauv tsev: cov khib nyiab hauv tsev, thiab lwm yam.

6. Diction los yog extract: seaweed extract, ntses extract, thiab lwm yam.

1. Semi-ntub khoom crusher yog siv los ua kom nws yoog raws cov dej noo ntawm cov ntaub ntawv raw.

2. Lub tshuab particle txheej ua rau lub ntsej muag particle loj tsis sib xws, qhov saum npoo yog du, thiab lub zog siab.Haum rau kev sib txuas nrog ntau yam granulators.

3. Tag nrho cov kab ntau lawm yog txuas nrog siv conveyor thiab lwm yam khoom siv txhawb nqa.

4. Cov qauv tsim, kev ua haujlwm ruaj khov, kev ua haujlwm yooj yim thiab txij nkawm.

5. Cov cuab yeej tuaj yeem xaiv raws li koj xav tau tiag tiag.

Cov txheej txheem muaj xws li fermentation khoom, tov khoom, granulation tshuab, tshuab ziab khaub ncaws, txias, roller sieve tshuab, silo, tag nrho automatic ntim tshuab, ntsug crusher, siv conveyor, thiab lwm yam. fermentation → sib tov ntawm cov khoom xyaw (sib tov nrog lwm cov organic-inorganic cov ntaub ntawv, NPK ≥4%, organic teeb meem ≥30%) → granulation → ntim.Nco tseg: cov kab ntau lawm no tsuas yog siv rau kev siv xwb.

1. Nruas dumper

Cov txheej txheem fermentation tag nrho decomposes cov organic pov tseg rau hauv fermentation thiab ripening.Cov plugs sib txawv xws li taug kev dumpers, ob-helix dumpers, grooved plugs, groove hydraulic dumpers thiab tracked dumpers uas tsim los ntawm peb lub tuam txhab tuaj yeem xaiv raws li qhov tseeb composting raw cov ntaub ntawv, venues thiab cov khoom.

2. Crushing tshuab

fermented raw khoom nkag mus rau ntsug saw grinder, uas tuaj yeem tsoo cov ntaub ntawv raw nrog cov ntsiab lus dej tsawg dua 30%.Qhov loj me tuaj yeem ncav cuag 20-30 xaj, uas ua tau raws li qhov xav tau ntawm granulation.

3. Kab rov tav tov khoom

Tom qab crushing, ntxiv cov khoom pab raws li tus qauv thiab sib tov tusyees nyob rau hauv lub blender.Kab rov tav tov khoom muaj ob txoj kev xaiv: ib tug uniaxial tov khoom thiab ib tug ob-axis tov khoom.

4. Ib qho tshiab organic chiv granulator

Qhov tsim nyog granulation tus nqi ntawm lub tshuab yog siab li 90%, uas yog haum rau ntau yam sib txawv qauv.Lub zog compressive ntawm cov khoom yog siab dua li ntawm disk granulation thiab nruas granulation, thiab qhov loj kheej kheej tus nqi yog tsawg dua 15%.

5. Round pov

Lub tshuab rounding tuaj yeem kho thiab ua kom zoo nkauj ntawm granulation hais tom qab granulation.Tom qab extruding granulation los yog disk granulation txheej txheem, tom qab pov puag ncig, cov chiv chiv tuaj yeem sib txawv ntawm qhov loj me, qhov tseeb roundness, ci thiab du ntawm qhov chaw, loj particle zog, thiab spherical yield ntawm chiv yog siab li 98%.

6. Qhuav thiab txias

Lub tshuab ziab khaub ncaws tsis tu ncua tso cov cua sov hauv qhov cub cua kub ntawm lub qhov ntswg mus rau tus Tsov tus tw ntawm lub cav los ntawm cov kiv cua ntsia ntawm tus Tsov tus tw ntawm lub tshuab, kom cov khoom nyob rau hauv tag nrho kev sib cuag nrog cov cua kub thiab txo cov dej. cov ntsiab lus ntawm cov khoom.

Cov tub yees txias txias cov khoom ntawm qhov kub thiab txias tom qab ziab, thiab txo cov ntsiab lus dej ntawm cov khoom dua thaum txo cov particle kub.

7. Roller sieve

Nws yog tsuas yog siv los cais cov khoom tiav los ntawm cov khoom siv rov ua dua tshiab.Tom qab sieving, cov khoom tsim nyog tau muab tso rau hauv lub tshuab txheej, thiab cov khoom tsis tsim nyog tau muab pub rau hauv cov saw ntsug crusher kom rov ua dua, yog li ua tiav cov khoom faib thiab kev faib tawm cov khoom tiav.Lub tshuab txais ib qho kev tshuaj ntsuam ua ke, uas yooj yim los tswj thiab hloov.Nws cov qauv yog yooj yim, yooj yim rau kev khiav lag luam thiab du.Steady, nws yog ib qho khoom siv tseem ceeb hauv kev tsim cov chiv.

8. Ntim tshuab:

Cov txheej txheem ntawm cov khoom tsim nyog los ntawm lub tshuab rotary txheej tsis tsuas yog ua rau cov khoom zoo nkauj, tab sis kuj txhim kho cov tawv tawv ntawm cov khoom.Lub tshuab rotary txheej tau txais cov khoom siv tshwj xeeb ua kua txau tshuab thiab cov khoom siv hmoov txau tshuab kom zoo tiv thaiv cov hmoov av thaiv.

9. Tsis siv neeg ntim tshuab:

Tom qab cov khoom yog coated, lawv tau ntim los ntawm lub tshuab ntim khoom.Lub tshuab ntim khoom muaj qib siab ntawm automation, kev sib koom ua ke ntawm qhov hnyav, suture, ntim thiab kev thauj mus los, uas paub txog kev ntim khoom sai thiab ua rau cov txheej txheem ntim tau zoo dua thiab raug.

10. Siv conveyor:

Conveyor plays lub luag haujlwm tseem ceeb hauv cov txheej txheem tsim khoom, vim tias nws txuas qhov sib txawv ntawm tag nrho cov kab ntau lawm.Ntawm no compound fertilizer ntau lawm kab, peb xaiv muab koj nrog ib tug siv conveyor.Piv nrog rau lwm hom conveyors, siv conveyors muaj kev pabcuam loj, ua rau koj cov txheej txheem ntau lawm ua haujlwm tau zoo thiab kev lag luam.