Organic fertilizer processing flow

Lub hauv paus ntws ntawm cov organic chiv ua cov txheej txheem hauv qab no:

1.Raw cov khoom xaiv: Qhov no suav nrog kev xaiv cov khoom siv organic xws li tsiaj txhu, cov qoob loo residue, zaub mov pov tseg, thiab lwm yam khoom siv organic haum rau siv hauv kev tsim cov organic chiv.

2.Composting: Cov ntaub ntawv organic yog tom qab ntawd raug rau cov txheej txheem composting uas muaj kev sib xyaw ua ke, ntxiv dej thiab cua, thiab tso cai rau cov sib tov kom decompose raws sij hawm.Cov txheej txheem no pab txhawm rau rhuav tshem cov khoom siv organic thiab tua cov kab mob uas muaj nyob rau hauv qhov sib tov.

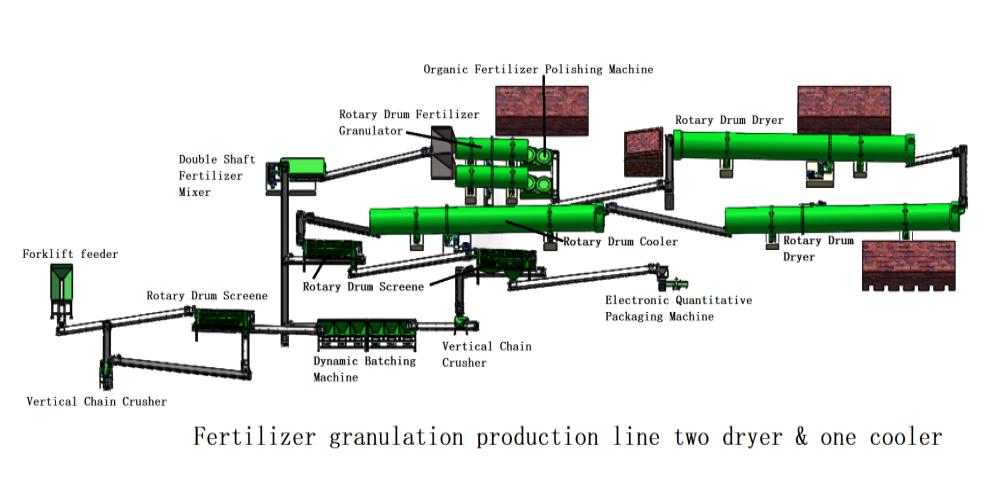

3.Crushing thiab sib tov: Cov ntaub ntawv organic composted ces crushed thiab sib tov ua ke kom ntseeg tau tias uniformity thiab homogeneity ntawm qhov sib tov.

4.Granulation: Cov khoom sib xyaw organic yog tom qab ntawd dhau los ntawm cov organic chiv granulator los tsim cov granules ntawm qhov xav tau loj thiab cov duab.

5.Drying: Cov organic chiv granules ces qhuav kom tshem tawm cov dej noo ntau dhau siv lub tshuab ziab khaub ncaws.

6.Cooling: Cov qhuav organic chiv granules yog txias siv lub tshuab txias txias kom tsis txhob overheating thiab tswj lawv zoo.

7.Screening thiab muab qhab nia: Cov organic chiv txias granules yog tom qab ntawd dhau los ntawm cov tshuaj ntsuam xyuas chiv kom cais cov granules loj los yog undersized thiab muab qib raws li lawv qhov loj me.

8.Packaging: Cov kauj ruam kawg yuav tsum ntim cov graded organic chiv granules nyob rau hauv lub hnab los yog lwm yam ntim npaj rau siv los yog faib.

Cov kauj ruam saum toj no tuaj yeem hloov kho nyob ntawm qhov tshwj xeeb yuav tsum tau ua ntawm cov organic chiv cog qoob loo lossis hom organic chiv raug tsim.