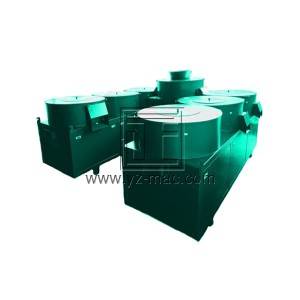

Inclined Sieving Solid-kua Separator

Nws yog ib qho khoom siv tiv thaiv ib puag ncig rau excrement lub cev qhuav dej ntawm nqaij qaib quav.Nws tuaj yeem cais cov dej phwj nyoos thiab quav los ntawm cov tsiaj txhu pov tseg rau hauv cov kua organic chiv thiab cov organic chiv.Cov kua organic chiv tuaj yeem siv rau kev siv qoob loo tom qab fermentation, thiab cov khoom organic chiv tuaj yeem siv rau thaj tsam ntawm qhov tsis muaj chiv uas tuaj yeem txhim kho cov qauv av.Nyob rau tib lub sijhawm, nws kuj tuaj yeem ua cov organic compound chiv.Lub twj tso kua mis txhawb nqa yog siv los xa cov dej chiv thawj mus rau qhov sib cais, thiab cov khoom siv (qhuav quav) yog extruded thiab sib cais los ntawm cov kauv axis muab tso rau hauv qhov screen, thiab cov kua ntws tawm ntawm qhov hluav taws xob los ntawm lub sieve.

CovInclined Sieving Solid-kua Separatoryog tsim los ntawm sieve, kauv winch thiab kauv hniav, uas yog ua los ntawm zoo 304 stainless hlau thiab alloy tom qab tshwj xeeb txheej txheem.Nws muaj zoo corrosion kuj thiab hnav tsis kam.Nws muaj 2-3 zaug ntawm kev pabcuam nqa piv nrog cov khoom zoo sib xws.

Kev teeb tsa kev ua haujlwm ntawm inclined sieve solid-kua separator yog tiav thiab tsom.Tag nrho lub tshuab tsim ua ke ua ke nrog cov khoom siv khib nyiab, kev vibration system, extrusion system thiab tsis siv neeg flushing system, uas txhim kho lub peev xwm thiab kev kho mob.

1. Nws yog lub cim tshiab ntawm cov khoom pov tseg ib puag ncig tiv thaiv.

2. Ua zoo kho cov khib nyiab pov tseg los ntawm cov tsiaj nyeg thiab nqaij qaib ua liaj ua teb rau kev sib cais cov kua-kua.

1.Nws muaj kev ua haujlwm ntawm kev txheeb xyuas thiab lim cov khoom loj ua ntej, thiab ua ke ntau yam haujlwm xws li kev sib kis, nias, lub cev qhuav dej thiab xuab zeb tshem tawm los daws cov teeb meem ntawm cov khoom siv khib nyiab winding thiab airtight kev ua haujlwm.

2.Qhov kev sib cais ntawm ntab, tshem tawm cov teeb meem thiab sediments hauv cov khib nyiab yog ntau tshaj 95%, thiab cov ntsiab lus ntawm cov khoom pov tseg yog ntau tshaj 35%.

3.Nws muaj kev tswj cov kua dej tsis zoo, uas txuag tau ntau dua 50% ntawm kev siv hluav taws xob ntau dua li cov cuab yeej zoo sib xws, cov nqi khiav haujlwm qis.

4.Qhov ib feem ntawm cov khoom siv nyob rau hauv kev sib cuag nrog cov khoom nruab nrab yog ua los ntawm high-zoo stainless hlau thiab yog passivated los ntawm pickling.

Lub hauv paus parameter yog raws li nram no:

| Qauv | Peev xwm (m³ / h) | Khoom siv | Lub zog (kw) | Slagging-off Rate |

| 20 | 20 | TIAB SA 304 | 3 | > 90% |

| 40 | 40 | TIAB SA 304 | 3 | > 90% |

| 60 | 60 | TIAB SA 304 | 4 | > 90% |